SolFab is specially designed to meet the needs of the dental industry

Products

The SolFlex 3D printer family consists of 3D printers of various print volumes. Depending on the production units and manufacturing needs, the SolFlex portfolio offers the suitable solution for each enterprise. All SolFlex printers combine patented parts and processes which meet the highest quality standards. Every millimeter was designed, engineered, built, and assembled to the most exacting performance standards.

Unique Technology

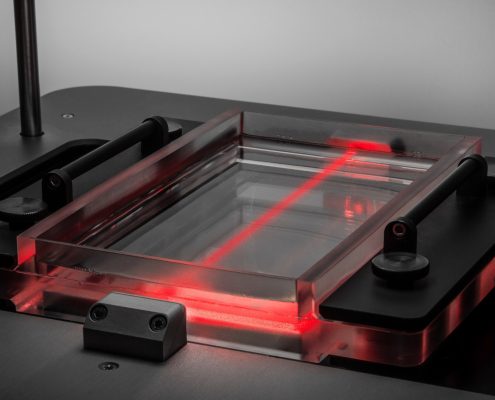

Patented Vat Technology

Excellent printing results.

The patented FlexVat is specially designed to minimize peeling forces during the printing process, resulting in a highly efficient print job.

Moving DLP Light Projector

Highest precision.

The unique and innovative moving DLP design allows you to print out large scaled objects with high resolution. In addition, the 3D printers are equipped with the newest generation of UV LEDs and precise UV optics, ensuring fast printing speeds.

Sensor Monitored Production

Stable printing process.

The UV Light Dosage Monitoring Unit controls the process parameters, simplifies remote maintenance and ensures repeatable results.

Fast printing process.

The patented VDFS (Vat Deflection Feedback System) monitors and controls the separation process and thus saves up to 40% of manufacturing time.

Innovative Design

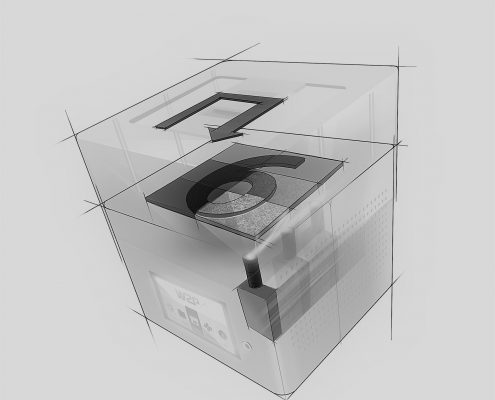

Optimized Print Volume

Compact desktop size.

We found a way to shrink the size of a 3D printer by increasing the building volume to the maximum, turning the SolFlex printer into true desktop factories.

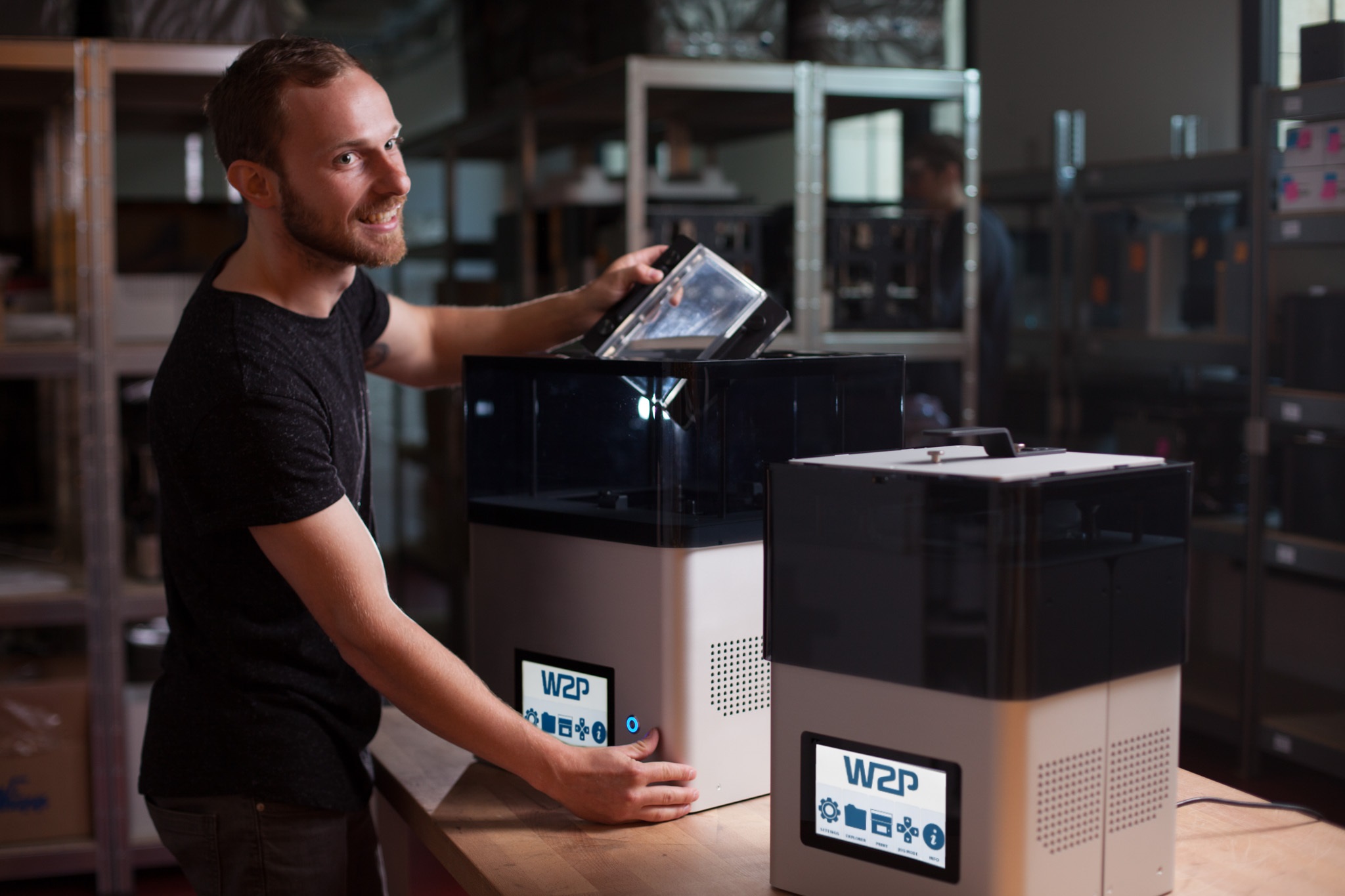

Superior Quality

Powerful machines.

The SolFlex 3D printers have been designed by experts and are hand crafted in Austria, using only high-quality components. The results are innovative machines performing at the highest levels.

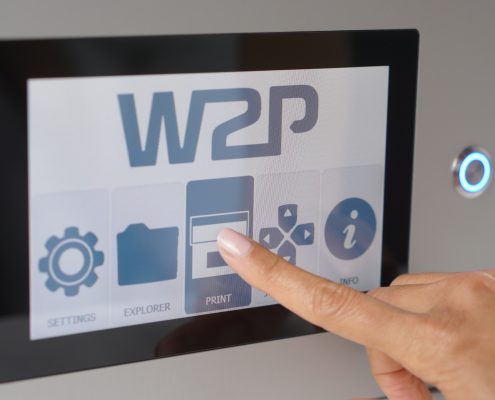

Touch Screen

Easy to use interface.

The Graphical User Interface (GUI) of the SolFlex printers allows users to easily access all the necessary printing information directly on the printer – even without any connection to the computer.

The patented VDFS (Vat Deflection Feedback System) monitors and controls the separation process and thus saves up to 40 % of manufacturing time.

The patented VDFS (Vat Deflection Feedback System) monitors and controls the separation process and thus saves up to 40 % of manufacturing time.